WAAM3D Equipment for Large High Tech Industrial Manufacturing

Revolutionizing WAAM3D Robotics with Real-Time Data Processing and UI.

Our Client.

WAAM3D was founded in 2018 to transform the research discoveries of Cranfield University into a commercial product. WAAM3D aimed to create a supply chain to enable the business development of a wire-based AM system; a robot featuring world-leading 3D printing functions. WAAM processes have been designed to accommodate large-scale engineering parts. The variety of processes available also means that WAAM3D have the flexibility of moulding their system around the needs of their clients. WAAM benefits their clients by reducing manufacturing times costs and waste, simplifying supply chains and removing fabrication. WAAM has the potential to benefit an impressive array of industries including aviation, defence, renewables and even space.

Our challenge

The WAAM robot is currently operated using pre-uploaded programs. This means that data processing cannot be carried out in real-time; leading to inefficient processes and a slow response time.

WAAM3D wanted to transform the data processes and visualization of their user interface, converting them into real-time. This would increase the reaction time of the system, and ensure that the information was always kept up to date; making it more user friendly and easy to use.

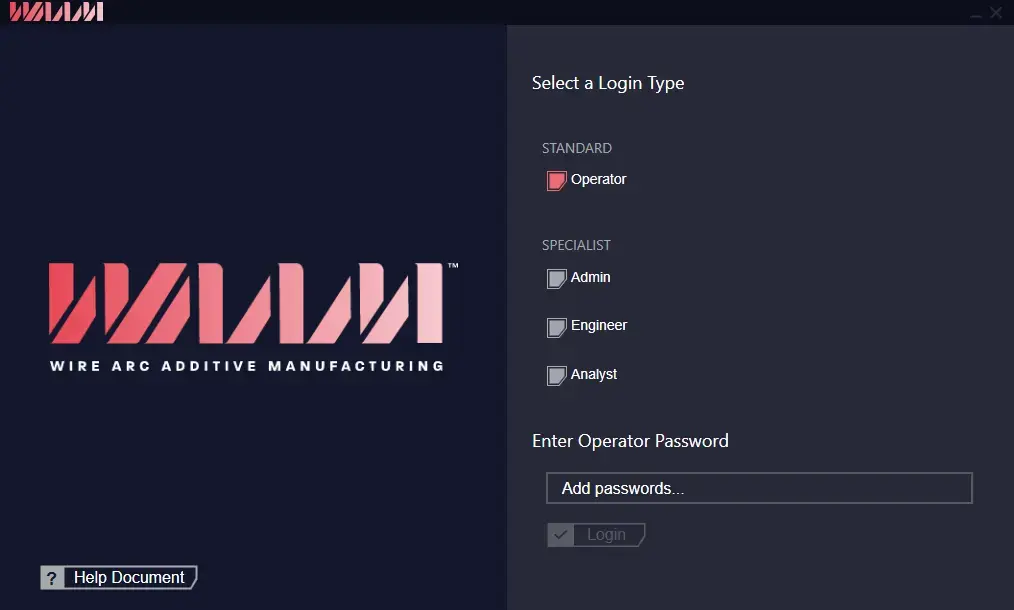

To achieve their data processing goals, WAAM3D asked another company to design the UI for their project, and tasked us with the responsibility of implementing it.

Our solution

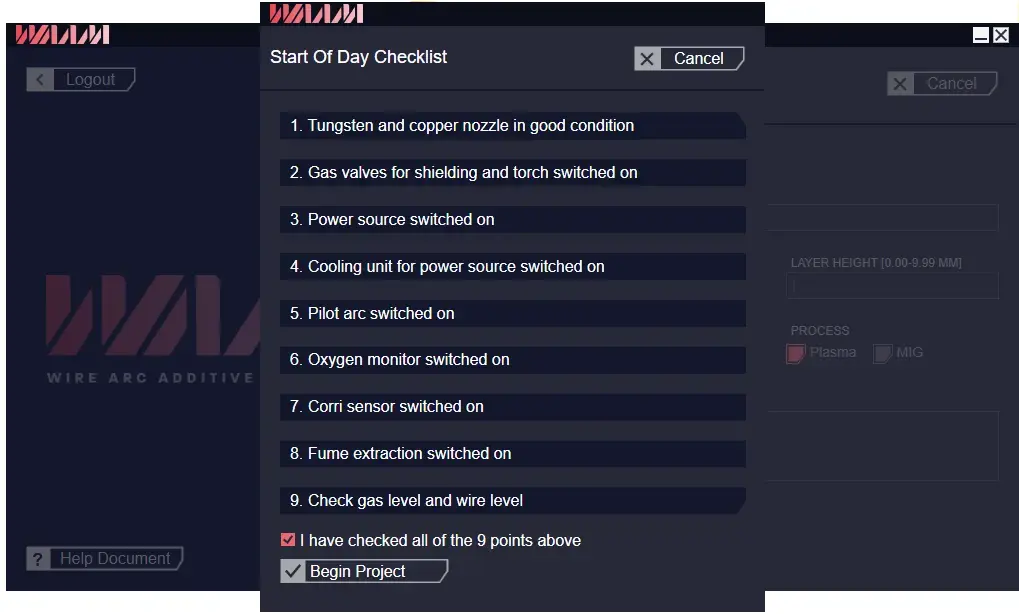

The main features of our application includes;

- A graphical display detailing the main features of the KUKA robot. This includes information about the wire position, arc voltage and lead temperature among other factors.

- An alarm to inform the operator that an error has occurred within the system if something goes wrong.

- A visualization tool to display a graphical version of the 3D product being printed

- The ability to view important information about the different elements within a product simultaneously, like the oxygen levels or lead temperature.

- A function allowing users to connect the application with a remote database. This allows workers in one factory to check or analyse the welding process of a product based in another factory.

- A database containing the main information of a project. This can be exported to a csv file, which means the database can be easily sent to analysts using emails.

- An overview of all events that have occurred within a project

A story of success

Our application provides a number of important benefits to improve the use of the WAAM robot. These include;

- The ability to check and monitor the main features of the robot in real-time means that users can respond to changes or problems quickly, and adjust the program accordingly. This provides WAAM3D with a more efficient and effective way of working.

- The 3D graphical representation of products allows engineers to pinpoint elements or events of interest that need to be changed or that provide important information for the 3D printing process.

- The opportunity for engineers to review the full history of events within a project allows them to build up a good understanding of the impact of each element or event of a project on each other.

- The ability to connect the application to a remote database provides many practical advantages. For instance, this feature makes it easy for engineers to check the details of a robot being installed in one country, without having to actually travel to that country.

Project facts

- Team – Developers 3, QA 2, BA 1, PM 1

- Project management – Scrum for production

- Technology – Net.Core 3.1 WPF, Ab3d.PowerToys WPF 3D toolkit library